The Complexities of Cannabis Vapor Testing

Until recently, there were no aerosol testing standards or regulatory requirements for cannabis vapor testing and the analysis of aerosols emitted from cannabis vaping devices anywhere in the world.

In 2022, Colorado state regulators passed requirements for testing vapor emissions for, at minimum, arsenic, cadmium, lead, and mercury.

Despite the popularity of both cannabis and nicotine-based e-juice vapes, there is no list of “vape safe” ingredients. In many ways, producers are learning as they go in terms of how heating these extracts affects human health.

Cannabis Users Value Safety & Quality

With the 2019 EVALI vape crisis in the U.S., the 2020 COVID-19 pandemic, and the ever-sharpening focus on consumer health and safety, concerns about potentially harmful compounds and adulterants found in cannabis vaping products continue to grow. As a result, Health Canada has banned vitamin E acetate from cannabis products and several provinces have been considering banning vape devices completely.

The lack of testing standards and regulatory guidance leaves industry and government at risk of allowing products on shelves that could have potential adverse health effects.

Cannabis Vapor Testing Isn’t A Problem – Until It Is

With the legal cannabis industry gaining credibility in Cananda, the U.S., and elsewhere, it’s imperative to demonstrate safety and distinguish cannabis products from those that cause negative health effects.

Licensed producers and processors can assure risk management and quality control by sharpening focus on consumer health and safety during the product development phase.

You can do this by seeking out a cannabis testing laboratory that has an established, step-by-step plan for testing cannabis extracts, vapor, and vaporization devices to ensure your product quality and safety can be verified with reliable results.

Why Testing Vape Liquids Isn’t Enough

Just passing the regulated test isn’t enough when it comes to assuring quality control in your vape products. Companies have the opportunity to set new standards and raise the bar – and consumer expectations – to new heights.

But, where do you start when you aren’t even sure where the problem might arise?

Licensed producers and processors need to dive deeper than simply testing their vape liquids. There are multiple places where things can break down:

- Is the battery leaching metals?

- Is your vape device running too hot for your formula?

- Is it doing what you think it is doing?

- Does it function the same over time?

Liquid testing alone is not enough. Comprehensive vape testing must include the analysis of vapor emitted from the device. It may not yet be part of the mandatory testing required under the Cannabis Act, but that doesn’t make it any less necessary.

4 Challenges of Cannabis Vapor Testing

There are four main challenges when it comes to testing cannabis vape products:

- Extreme variability in vapor systems and devices.

- Multitude of puffing parameters required to test device delivery.

- Yields of vapor devices are very small.

- Stringent procedures are necessary to avoid contamination.

We explain those challenges more in this Stratcann article about why government should help drive emissions testing.

The good news is, the team at Labstat has been testing vape devices for decades. Our experts have developed a comprehensive testing protocol specifically for cannabis vape devices to help you mitigate risk and protect your customers.

Whether you’re just beginning the product development phase, or your products are already on the market, we partner with your internal teams to meet your unique needs.

Setting the Standard in Cannabis Smoke and Vapor Testing

Your ability to obtain reliable, defensible product data, has never been more critical. Rest assured, we’re here to help. As a world leader in smoke and vapor analysis we’re experts at obtaining consistent and meaningful data to support your business.

Derived from the regulations and standards governing tobacco and e-cigarettes, the Labstat Emissions Testing Protocol identifies chemical risks associated with both the cannabis extract, and the resulting vapor emissions. And it works with any vape device.

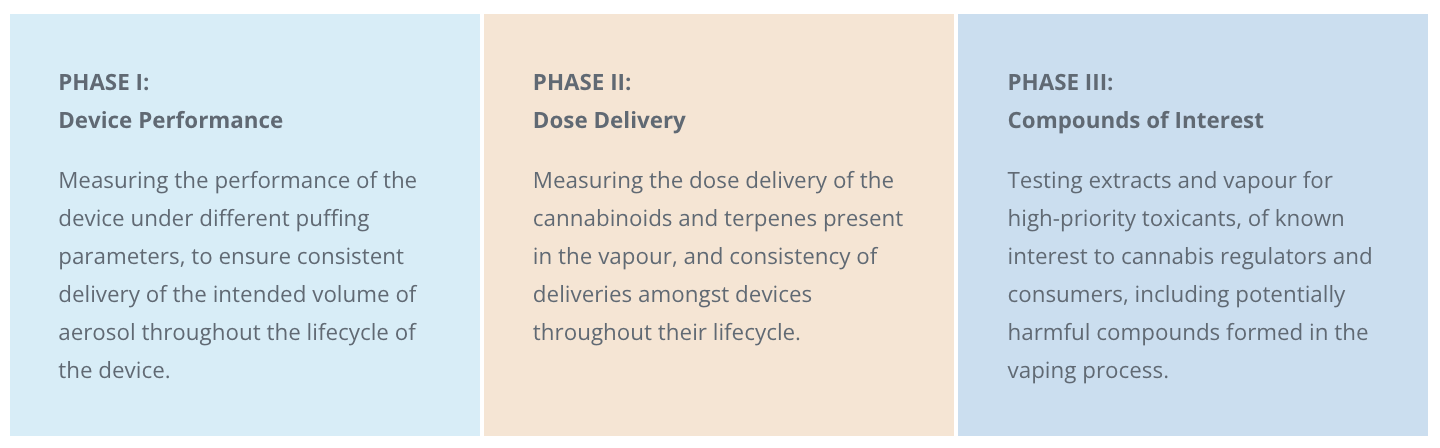

The Labstat Emissions Testing Protocol is a phased testing approach designed to answer these key questions:

- Is the product performing as designed (i.e. delivering compounds of interest as intended); and

- Is the product performing as expected, or is it generating unintended compounds or degradation by-products?

Each phase builds on the previous, to develop a technical understanding of the harmonization between the device, the formulation, and the resulting vapor.

Phase 1 | Device Performance

Phase one measures the performance of the device under different puffing parameters to ensure consistent delivery of the intended volume of aerosol throughout the lifecycle of the device. We evaluate both the cannabis extract and the resulting vapor in all our vape testing.

Does the device deliver the intended amount of vapor every time? Our performance testing accounts for device-to-device variability and harmonization of devices to the cannabis liquid.

It’s important to remember that the same vape device may perform differently when used with various types of extracts. Viscosity, density, and atomizer designs all influence the interactions between the liquid and the device. In addition, different cannabinoids and terpenes will distill into the vapor at different times during the lifecycle of the cartridge. This will alter the potency and flavour profiles, as well as the production of unwanted by-products during vaping.

In addition to the Health Canada Standards, the Labstat Emissions Testing Protocol examines cannabinoids, terpenes, metals, dicarbonyls,, adulterants, volatiles, major yields, ammonia, pH, density, aromatic flavourings, and propionic acid.

Phase 2 | Dose Delivery

In phase two, we measure the dose delivery of cannabinoids and terpenes present in the vapor and consistency of deliveries among devices throughout their lifecycle. Just because the cannabis liquid passed the accuracy test does not ensure that the product maintains those numbers in vapor form.

Our vape testing looks at “puffing regimes” from multiple sessions throughout the life of a cartridge. These puffing regimes are made of one puff collection over the course of 50 puffs. In order to pass, a product must maintain dose delivery in a minimum of seven puffing regimes to pass.

Puffing regimes are not aimed to represent all adult smoking behavior, but rather to create a baseline for regulatory and testing purposes. Our team of vape experts works with you to determine the most appropriate puffing regime for your product.

This is how you ensure your customers are having a consistent experience on day one and day 101. If you have ever seen a photo of a clogged, leaking vape cartridge you know this is important – products can change over time, don’t let yours be one of them.

In a market this competitive, brands don’t always get a second chance – get it right the first time

Phase 3 | Compounds of Interest

In this stage we conduct essential comparisons between contaminants present in the aerosol to those in the extract. This crucial step examines how a product liquid changes properties through the heating process.

We test both extracts and vapor for high-priority toxicants of known interest to cannabis regulators and consumers. This vigilance testing looks for known adulterants, such as vitamin E and fatty acids, and other potentially harmful compounds formed in the vaping process.

In the absence of prescribed guidance for cannabis vape device aerosol testing, reasonable list of compounds of interest could be inferred from the U.S. FDA’s Guidance for Harmful and Potentially Harmful Constituents (HPHC), as applied to Electronic Nicotine Delivery Systems, or other regulatory bodies providing guidance for nicotine e-vapor products.

This category will continue to evolve as additional adulterants that can impact human health are identified. Phase three is essential for due diligence, quality assurance, and risk management.

Begin Your Cannabis Vapor Testing Now

Customization is key given the diverse range of devices and extracts. A testing plan should be tailored to the specific parameters of the device, extract, and consumer behaviours. The flexibility of the Labstat Vape Testing Protocol™ phased approach is that it allows product developers to halt testing at any phase if there are product-related issues, saving both time and money.

Don’t wait until the regulations force you to perform comprehensive testing on your vape devices, work with a reputable lab to develop a customized testing plan that ensures you’re mitigating risks and protecting your customers health.

Contact us to talk about a cannabis vapor testing protocol for your products.