Stability Testing for Dietary Supplements & Natural Health Products: A Review of the Requirements

Stability testing for dietary supplements and natural health products (NHP) is vital for ensuring the quality, efficacy, and safety of your products. It helps determine how a product’s quality and characteristics may change over time under specific storage conditions, thereby informing the product’s shelf-life and storage instructions.

It also plays a key role in product development and market authorization, helping manufacturers identify potential issues early in the product development phase, reducing the risk of commercial interruptions and product recalls.

Health Canada Requires Stability Testing for Dietary Supplements & NHP

In addition to the benefits we just outlined, there is another vital reason to perform stability testing for your dietary supplements and natural health products: Health Canada requires it to sell your products in the country.

Let’s look at the regulations.

What the Natural Health Products Regulations Require

Section 52 of Health Canada’s Natural Health Products Regulations say this:

“Every manufacturer and every importer shall determine the period of time during which, after being packaged for sale, the natural health product will maintain its purity and physical characteristics and its medicinal ingredients will maintain their quantity per dosage unit and their potency when

(a) it is stored under its recommended storage conditions; or

(b) if it does not have recommended storage conditions, it is stored at room temperature.”

Manufacturers can meet these regulatory requirements through stability testing protocols for their dietary supplements and NHP.

Health Canada’s Quality Guide for Natural Health Products

To help industry design appropriate stability testing protocols, Health Canada provides comprehensive guidelines to assist manufacturers and stakeholders in conducting stability testing. These guidelines are in line with international standards, making them applicable and beneficial for global markets as well.

In essence, the guidance document says that the product license holder is ultimately responsible for ensuring stability, even when delegated to a third party, as compliance could be assessed during the site licensing process, as outlined in the Good Manufacturing Practices guidance document.

In Section 2.4.2 of the GMP document, you will find the 8 steps that manufacturers and importers of dietary supplements and natural health products must take to meet GMP requirements for stability testing for dietary supplements and NHP:

- Use data from accelerated or real-time stability studies or from similar product formulations to make an initial determination of the expiry date.

- Provide data and rationale to reasonably ensure that each finished product meets its label claims at the expiry date.

- Confirm and adjust the expiry date, when required, on the basis of real-time studies on product stored in the conditions noted on the label, for the period of time indicated by the expiry date.

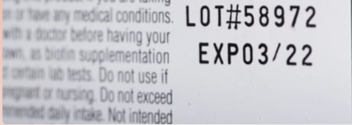

- Display the lot number and expiry date on the label of each finished product.

- Ensure that all packaging and labelling requirements are met, and that the product will remain free from contamination until the expiry date (e.g. deterioration of packaging material and labelling).

- Establish the shelf life from the date of original batch fabrication.

- Re-evaluate the product shelf life when significant changes are made to the formulation, manufacturing process or package that may affect the product’s stability.

- Carry out testing appropriate to each product.

Key Components of Stability Testing for Dietary Supplements and NHP

Let’s take a closer look at the different types of tests that can comprise a stability testing protocol for dietary supplements and natural health products.

Several tests are available to evaluate different aspects of a product’s stability. The specific tests required may vary depending on factors such as the product’s formulation, intended use, and available scientific literature. The common types of tests conducted during stability testing can be categorized as follows:

- Physical Tests:

- Appearance: Assessing changes in the product’s color, clarity, and particulate matter.

- Odor: Evaluating any alterations in the product’s smell or odor.

- Texture: Checking for any changes in viscosity, consistency, or physical form.

- Chemical Tests:

- Assay: Measuring the concentration or potency of active ingredients using validated analytical methods.

- Chromatographic Techniques: Using methods like high-performance liquid chromatography (HPLC) or gas chromatography (GC) to analyze the product’s chemical composition and identify any degradation products.

- Spectroscopic Analysis: Using techniques such as UV-Vis spectroscopy or infrared spectroscopy to assess the product’s chemical characteristics.

- Potency Tests:

- Quantitative Analysis: Determining the concentration of specific active ingredients or marker compounds to ensure the product’s potency.

- pH Measurement:

- pH Testing: Monitoring the product’s pH to identify any significant changes that could affect its stability or compatibility with the intended application site.

- Dissolution Rate:

- Dissolution Testing: Assessing the rate at which the product’s active ingredients dissolve, ensuring proper bioavailability and efficacy.

- Microbiological Tests:

- Microbial Limits Testing: Evaluating the product for the presence of microorganisms such as bacteria, yeast, or mold that could compromise its safety and quality.

Real-Time and Accelerated Stability Testing for Dietary Supplements and NHP

Stability testing falls into two primary categories: real-time stability studies and accelerated stability studies. Each type serves a distinct purpose and offers unique benefits.

Real-Time Stability Testing

Real-time stability testing involves evaluating the product’s stability under normal storage conditions – temperature, humidity, and light exposure – that a product is likely to encounter post-manufacturing and during its distribution and storage. This type of stability testing provides a realistic scenario for how a product will react to environmental conditions over its proposed shelf life.

The key benefit of real-time stability studies is the accuracy and real-world relevance of the data they generate. They provide the most reliable information about how long a product will maintain its quality, safety, and efficacy under standard storage conditions. They are, therefore, integral in determining accurate expiry dates and ensuring that consumers receive the product at its best quality.

However, real-time stability studies can be time-consuming, often taking several months to years to complete, depending on the proposed shelf-life of the product.

Accelerated Stability Studies

In contrast, accelerated stability testing subject the product to conditions more severe than those encountered in normal storage. This typically involves higher temperatures and possibly increased humidity levels to speed up the rate of chemical degradation and physical changes.

The main advantage of accelerated stability studies is that they offer a faster way to predict a product’s shelf-life and to identify potential stability issues. This rapid feedback can be particularly valuable during the product development phase, enabling faster iterations of product formulations. It also helps manufacturers assess how a product might react to extreme conditions during shipping or if not stored correctly by consumers.

Despite their speed and efficiency, accelerated studies should not replace real-time studies but should be used in conjunction with them for a comprehensive stability assessment.

Guidance to Design Your Stability Testing Protocols

For companies looking for guidance in developing a comprehensive stability testing protocol, it is advisable to consult experts in stability testing. Navigating the regulations for stability testing of dietary supplements and natural health products can be challenging due to differing interpretations between markets and often ambiguous areas.

Labstat, with its decades-long experience and understanding of regulatory standards, can guide you in achieving compliance while meeting your budget. Our stability chambers cover zone II (25C/60%RH) and zone IVa (30C/65%RH).