Cannabis Testing for Microcultivators in 3 Steps

The cannabis industry presents opportunities for micro cultivators and processors but also presents a challenging landscape marked by stiff competition, complex licensing, and tight margins. Crucial to navigating this terrain is prioritizing cannabis lab testing, which goes beyond regulatory compliance to enhance product safety and quality across various forms such as whole flower, isolates, distillates, and edibles.

This practice not only adheres to regulations but also sets a high standard benefiting consumers and profitability. Integral to product development and supply chain management, proper lab testing provides vital analytical data for informed decision-making.

Establishments like Labstat offer invaluable assistance, delivering expert guidance on licensing, regulatory compliance, and testing, thus laying a foundation for your business’s success.

Finding the Right Lab Partner

A good relationship with a testing partner can not only secure your brand but play a significant role in building quality, reliability, and consistency into your products. Lab testing will ensure your products are safe for public consumption, confirm potency, help meet regulatory standards, and reduce product liability.

Selecting a laboratory to conduct product testing is an important process and should never be based on price alone. Your cannabis testing lab is vital to verifying product quality and protecting your brand, so choose wisely.

To make the right choice for your business, micros should vet laboratories like they would when selecting any partner.

What to Ask Your Potential Cannabis Testing Lab

Qualify the lab’s capabilities with a thorough questionnaire, share your specifications, and visit them often. The more you engage your lab during the selection process, the fewer surprises you’ll have in the future.

It’s also important to ask the right questions of your lab to avoid costly lessons down the road.

Experience: Does the lab specialize in your area of business and have experience with your product types?

Reputation & Trust: Does the lab have reliable quality control systems, understand your specific needs, and is it transparent and accountable?

Method Validation: Does the lab have reliable testing methods to ensure accuracy for all matrices?

New Products: Does the lab have a full spectrum of experience for testing all types of consumable products?

Customer-Centric: Does the lab collaborate with you through careful planning, detailed experiment design, and educational discussions?

Step One | Batches vs Sampling

This first step in product testing is collecting what is called a representative sample.

Think of a national survey. To represent Canada as a whole, the survey would need to include a large and diverse group of respondents. You would need to sample a large enough cross-section of the population so your survey results are representative of all Canadians. The same concept applies to collecting a sample for analytical testing.

What is a Batch?

A batch is defined as a set of plants grown under the same conditions, at the same time.

There isn’t a regulatory standard on what constitutes a batch; micros should clearly define what a batch means for them and be sure to take into consideration the implications of batch definition on your operations.

The reason you need to define a batch is because every batch should be tested to establish safety and potency.

What is Sampling?

Sampling has defined regulatory perimeters, unlike batches. A sampling is the selection of a subset within a whole in order to estimate the characteristics of the whole.

There are documents available that provide guidance on how botanicals and plant materials are to be collected.

For example, under the Cannabis Act and GPPs, sampling batches should be conducted in accordance with the European Pharmacopeia section 2.8.20 “Herbal Drugs: Sampling and Sample Preparation.”

This document provides specific guidance on the number of samples to be collected from a batch and the minimum mass of those samples.

Tips for Effective Sampling

When sampling a batch, it is vital that you don’t introduce what is referred to as a bias.

It is easy to bias the results of cannabinoid testing, both low and high, just based on the composition of the sample you collect. The cannabinoid concentration is not equal across all parts of the plant. If you were to sample more stems than leaves, for example, you could be introducing a bias that results in a low cannabinoid content.

Conversely, by sampling more flowers than are included in standard packaging, you introduce a bias toward higher cannabinoid concentration, resulting in false label claims.

Step Two | Required Testing

Most laboratories are like all-night diners. They have a huge menu of tests they can perform and it is up to the customer to order what they need. This can be a challenging endeavor if you aren’t sure what tests are required. That’s why building a partnership with your lab is such an asset.

There are a variety of tests that can be performed on cannabis products and their raw material inputs. Collaboration is key when it comes to determining your testing regimes; the right lab partner will be able to explain the nuances of required and recommended testing to help you develop a plan.

Don’t be afraid to reach out to a lab and ask them what regulatory packages they offer for testing your cannabis products. Look for labs that walk you through the process and break it down in a digestible way.

Regulatory Testing for Cannabis

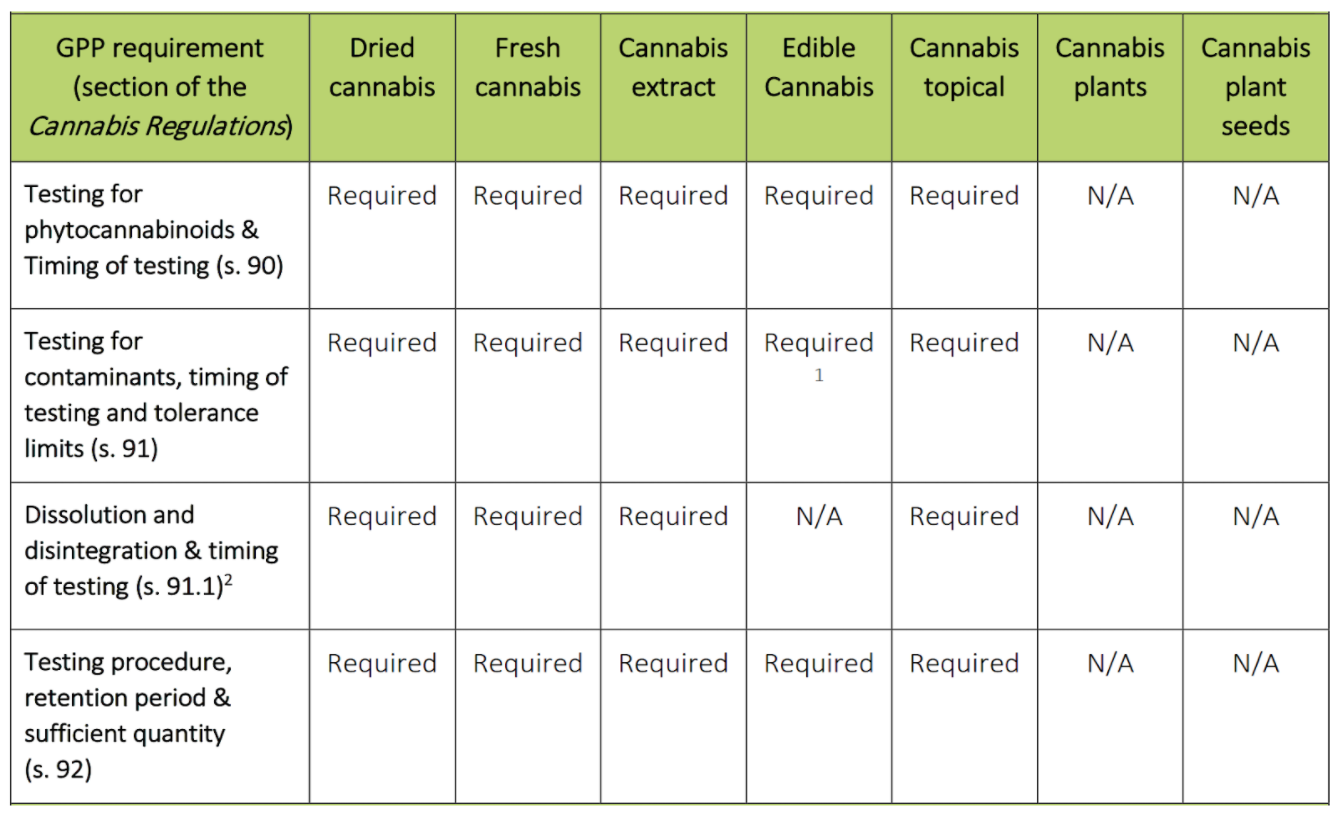

As you can see in the chart below, there is a basic regulatory framework in place around the required testing for the various cannabis product formats. This is by no means an exhaustive breakdown of the testing labs will offer, but it does include the basic testing requirements for cannabis products.

All formats will require at minimum an assessment of potency and demonstration of no microbial contamination.

Step Three | Analyzing the Results

The last major hurdle in testing your product is understanding the results. Since there is no set standard for how results are reported, this is quite possibly the most daunting step for any producer, but especially for micros if you don’t have a full-time QAP on staff.

A good laboratory partner will ensure you’re an informed consumer and will never shy away from answering questions about how they report their results.

What to Look for in a Certificate of Analysis

The results from your cannabis tests will be presented on what’s called a Certificate of Analysis. Learning to analyze your test results may involve learning a new vernacular.

If you’re unsure, your lab can help you understand the terminology and acronyms related to the various units. Certificates of Analyses should be well organized and tidy to ensure they provide a detailed summary of all testing performed.

Know the Test Methods Being Used

It’s important to note that all test methods are not created equal.

Cannabinoid content can be calculated in different ways, so be sure you know which methods your lab is using and whether or not it’s been validated for your product type.

For example, how do they calculate the total THC content of a cannabis product? It seems simple enough but how tests determine potency is vital, not just for meeting regulations but for product safety as well.

For instance, THC and THCA are both taken into account when determining total THC content. However, these two molecules have different weights, so it isn’t as easy as simply adding them together. Doing so would underestimate the total THC content, which is why the industry standard is to adjust for the differences in molecular weights.

Test for More than Just Potency

There are additional tests that can be run to assess the various quality attributes of your product.

Terpene testing can provide insight into the effectiveness of your drying and curing processes. Water activity and moisture content can be informative of shelf-life, stability, and resistance to microbial growth – all key aspects of stable edible products.

Trace analyses such as heavy metals and pesticides require specialized instrumentation and highly skilled analysts; ask if your lab has validated their methods. Some of these tests may be required based on where your product lies on the cannabis value chain or supply chain.

Use Lab Testing to Build Your Brand

At the end of the day the lab will sell you anything you ask for just like the all-night diner. It is up to you to be an informed consumer.

Remember that the goals of cannabis lab testing reach beyond compliance; select a laboratory that works with you throughout the product development phases to ensure you’re building a world-class portfolio of products.

Contact our cannabis testing experts with questions about lab testing for your business.