Ensuring Shelf Stability in Cannabis Edibles: Best Practices and Key Considerations

Reviewed and Approved by Rana Tayyarah, Labstat VP, Scientific & Regulatory Affairs

1-Minute Summary

- Cannabis edibles’ shelf stability is crucial for maintaining product quality, potency, and consumer satisfaction.

- Current cannabis regulations lack comprehensive shelf stability standards, unlike the food industry.

- Key factors affecting shelf life include pH, water activity, temperature, packaging, and storage conditions.

- Labstat offers comprehensive shelf life testing, helping manufacturers ensure product consistency and gain a competitive edge.

Contact us to discuss your cannabis stability testing or keep reading for more.

Cannabis Edibles are Growing in Popularity

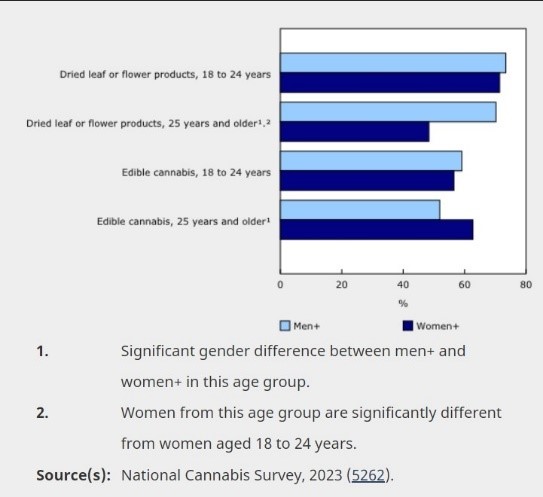

According to the National Cannabis Survey (2023), edibles are the second most consumed product type, with 57% of respondents reporting having consumed an edible in the previous 12 months.

In addition, our own data suggest edibles are the most likely product type to overtake flower as the most consumed.

Setting a “Best By” or Expiration Date

Consumers clearly enjoy cannabis-infused beverages, gummies, chocolates, and similar products. However, their experience with your product will influence whether they become a loyal customer or not. Beyond cannabinoid concentration and terpene profile, edibles present another variable to product consistency – shelf life and stability.

Conducting shelf life testing is the best way to obtain data about how your products will behave under different storage conditions. This information will help you establish the optimal “best by” and expiration dates for your products, improving the customer experience and safeguarding your brand.

In this article, we explain the factors that affect the shelf life of cannabis edibles and how testing is done to provide data on how your product will react to various storage conditions.

Understanding the Shelf Stability of Cannabis Edibles

For cannabis edibles, maintaining shelf stability ensures that the products retain their intended potency, flavour, and quality until consumed.

Unlike most foods and beverages that include “best-by” or expiration dates on their packaging, many cannabis edibles currently lack these indicators, which can lead to a negative experience if the product is outside of its best-by window.

What are the Regulations for Cannabis Edibles Shelf Life Testing?

The Cannabis Act includes numerous standards for packaging, labeling, and marketing cannabis-infused products. However, these regulations do not yet extend comprehensively to shelf stability.

In contrast, the food industry mandates shelf-life testing and clear expiry dates for all consumables.

As the cannabis industry evolves, many experts anticipate that similar standards will be applied to cannabis edibles, requiring proactive measures by manufacturers to ensure compliance and product safety.

Key Factors Influencing Shelf Stability

Let’s take a closer look at the factors that influence shelf life:

Composition Factors

- pH: The acidity or alkalinity of a product can significantly affect its shelf life. Foods with lower pH levels (high acidity) are less susceptible to microbial growth, thereby extending their shelf life.

- Water Activity: This measures the amount of free water in a product, which can support microbial growth and affect chemical stability. Lower water activity typically correlates with a longer shelf life.

Environmental Factors

- Temperature: Storage temperature can accelerate or decelerate the degradation of ingredients in consumer products.

- Packaging: Proper packaging can protect products from environmental factors that accelerate spoilage and degradation, such as light, oxygen, and humidity.

- Storage Conditions: Recommendations such as “store in a cool, dark place” or “refrigerate after opening” can help maintain product stability.

How is Shelf Life Testing Done for Cannabis Edibles?

Shelf life studies allow manufacturers to simulate various storage conditions to predict how their products will perform over time. For example, testing cannabis-infused chocolates under different temperatures and humidity levels can reveal the optimal conditions for maintaining their quality.

Shelf life testing for edibles begins with designing a testing protocol. If you’re new to stability testing, or have custom requirements, Labstat’s scientists can help you design a protocol that provides the data you need within your budget. Information needed includes…

- Assays to be performed during the study, such as Water Activity, Microbial Growth, Cannabinoid Concentration, etc.

- Time points at which the testing will be performed, such as Day 0, Day 7, Day 30, and so on. More time points increase the robustness of the data but also increase cost.

- Storage conditions for the product. Labstat offers multiple options, including…

- 25°C/60% RH (Zone II)

- 30°C/65% RH (Zone IVa)

- 40°C/75% RH

- Refrigerated and frozen conditions

- Real-time, intermediate, and accelerated testing

When testing products are received, they are uniquely identified and assays are performed on Day 0 to establish a baseline for the product. Products are transferred to assigned stability chambers set to the appropriate conditions. Our scientists will take sample pulls at the set time points to conduct the required assays throughout the course of the study.

Stability Testing Provides a Competitive Advantage

This offers you an opportunity to stand out in the market and demonstrate product stewardship. As the industry develops, shelf life testing for edibles may eventually become a regulatory requirement, but it pays to be proactive and conduct this testing now to build your brand.

Not every manufacturer is including “best by” and expiration dates on its products. Nor are they studying their products’ behaviour under various storage conditions to maximize quality. Consumers often look for expiration dates when shopping.

Contact Labstat to get the support you need for a stability study for your cannabis edibles.